Patented technology, with an Inner automatic thin-oil lubricating system, and a long oil change cycle.

The powder separator features variable frequency speed regulation and precise control of the discharge fineness. Additionally, it increases the grinding force of the grinding roller on the processed materials by about 15%-20%.

The micro-powder grinding mill requires fewer bearing replacements, has a longer service life, and the overall machine lifespan is 3-5 times longer than that of other grinding mills.

Under the same production capacity and fineness, it is more than 80% cheaper than the airflow mill. Additionally, the machine exhibits strong wear resistance, which enhances the service life of the equipment.

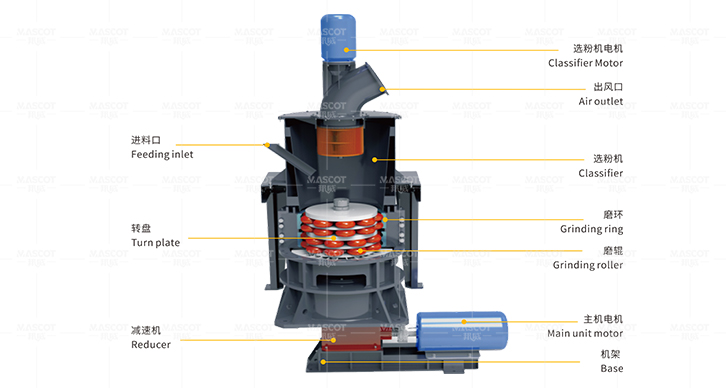

The large pieces of material are broken into small particles by the hammer crusher and then sent to the storage bin by the elevator. The electromagnetic vibrating feeder evenly distributes the materials to the center of the upper turntable. The materials are scattered to the periphery of the circle under the action of centrifugal force, and the materials falling into the ring are pressed, rolled, and ground by the rollers. The vortex created by the rotating turbine in the powder concentrator causes the coarse particles to descend back to the ground, while the fine powder is carried into the cyclone powder collector with the airflow.

| Model | Average diameter (mm) |

Ringing Roller/Roller Ring NO. | Input Size of Main Frame (mm) |

Finished Product Size | Capacity(t/h) | Power(kw) | Overrall Dimension L×W×H(m) |

||||||

| Ringing Roller (pcs) |

Roller Ring (pcs) |

Micron | Mesh | Main Grinder | Power Separator | Draft Fan | Feeder | Discharge Valve | |||||

| HGM80 | 800 | 21 | 3 | ≤ 10 | 5-47 | 3250-325 | 0.6-4 | 75 | 22 | 45 | 0.06 | 0.75 | 11.9×2.7×5.8 |

| HGM100 | 1000 | 27 | 3 | ≤ 20 | 5-47 | 3250-325 | 0.9-6 | 110 | 30 | 75 | 0.15 | 1.1 | 15.5×4.5×8.6 |

| HGM1036 | 1000 | 36 | 4 | ≤ 20 | 5-47 | 3250-325 | 1.2-10 | 132 | 37 | 75 | 0.15 | 1.1 | 18×4.6×8.6 |

*The output will vary according to different materials, feed particle size and other factors

50TPH Raymond Mill For Granite Processing In Jiangxi, China

40TPH Vertical Mill Production Line In Xinjiang , China

15TPH Grinding Mill Production Line For Gypsum In Ethiopian

10TPH YGM Grinding Mill For Limestone In Shandong, China

River Pebble Grinding and Processing

Gypsum Grinding and Processing

Bentonite Grinding and Processing

Green and Intelligent Mining Machinery

Manufacturing and Export Base

Based on high quality and perfect after-sales service, our products have been

exported to more than 120 countries and regions.